Introduction

As kids, most of us would have played with a magnifying lens to direct sunlight onto a piece of paper. What happens next? It starts burning, right? Likewise, Concentrated Solar Power (CSP) plants such as parabolic trough, parabolic dish, linear fresnel, and power tower, work in two parts. The first part contains lenses or mirrors that concentrate solar energy on to a receiver that collects the heat generated in this process. In the second part of the process, this heat is channelled to a conventional generator to produce electricity. While CSP is the most effective source of large scale renewable energy production it is not green technology in its entirety. It has many hidden environmental impacts, which are definitely lesser than that of a coal/lignite power plant but are still significant enough to be understood well and planned for. Let's have a look at the environmental impacts of the CSP plant.

Methodology

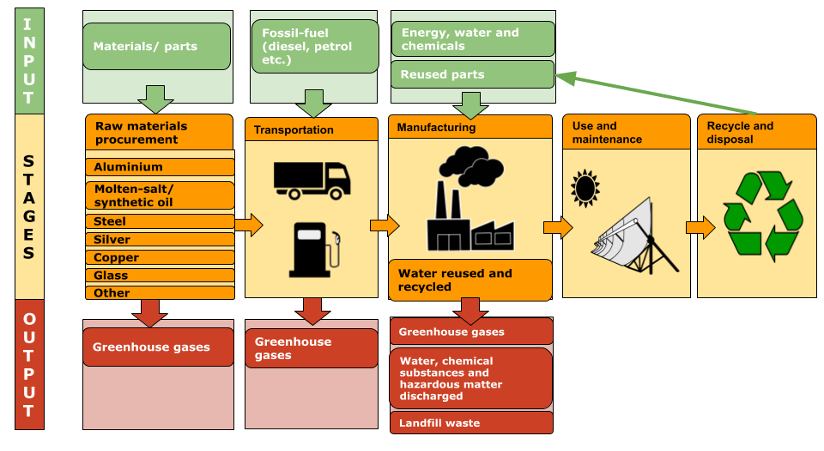

An eco-balance tool is used to measure the environmental performance of any product manufactured. This methodology was developed by the Institut für ökologische Wirtschaftsforschung (IÖW) in the late 1980s in Berlin and implemented by many leading German companies to calculate physical input and output right from the preliminary process of procurement of raw materials, to the manufacture, transportation, operation, maintenance, recycling and disposal of any product. It is similar to the inventory analysis for product life-cycle assessment. Out of the seven steps for eco-balancing, this article depicts step one, which is the “identification and analysis of environmental impact” for a CSP plant.

The risk potential

CSP plants can have many significant environmental impacts due to the mining of raw materials, waste generation, GHG emissions etc., during the various stages in its life-cycle. Even though the CO2 emissions of a CSP plant are much lesser than that of typical coal or other fossil-fired plants, during its operation, a typical CSP plant impacts the flora, fauna, land and water. Consequently, interfering with natural conditions like soil fertility, insect diversity and water availability.

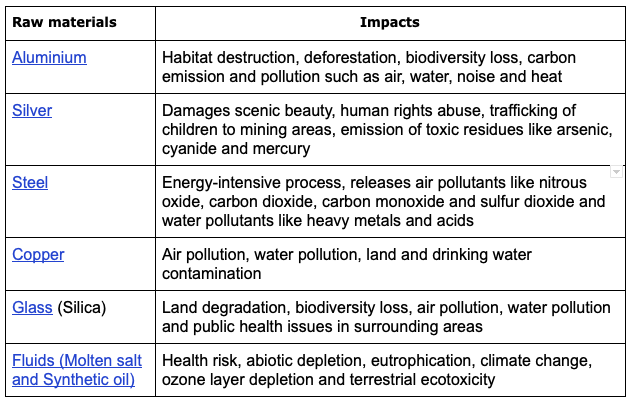

The raw materials typically used in the manufacture of a CSP and their impacts on the environment and health are listed below:

Table 1: Impacts of major raw materials used in the production of CSP plants.

After completing its efficient life of 30 years, more than 90% of the waste materials are recyclable and can be used in re-manufacturing of a CSP plant. Among the non-recyclable materials, heat transfer fluids like molten salt and synthetic oil are treated as hazardous waste, whereas the non-hazardous waste materials, unfortunately, end up in landfills.

Figure 1: Eco-balance of a CSP plant.

In the era of rising threats of natural and anthropogenic disasters, extreme weather events and public health issues, every country is looking for solutions to reduce the impact of the climate crisis. Conventional power plants are a major source of CO2 emissions in developed and developing countries. Solar power plants, as we have just seen, also have hidden environmental impacts, though these are admittedly, much lower than that of thermal power plants.

Non-fossil-fuel-based energy sources like hydrogen, algal biofuel and biogas, could therefore be utilised by industries as an alternative to ‘dirty energy’ from fossil fuels like coal, natural gas and oil. However, these energy sources are currently more expensive than conventional energy sources and need more research for meeting large-scale demand. Given our current levels of knowledge and capacity, retiring old and inefficient thermal power plants, swapping them with solar and a ban on new thermal power can make energy generation more economic and sustainable, in the long term. To make these changes pay, all countries have to reduce their consumption of domestic, commercial, agricultural and other energy use, as well as, the countries have to invest in carbon-free/ greener ways of energy generation.

Way out

Of the feasible technologies, CSPs are the greener way forward. The following steps can ensure that the environmental impacts of CSPs are minimised as much as possible:

-

Establish a waste collection and recycling station for decommissioned solar panels.

-

Further research to reduce the requirement of raw materials.

-

Recover and restore highly valuable materials like silver.

-

Repurpose and resell parts of CSP plants which are in good condition to support the circular economy.

-

Increase the use of recycled materials to set-up a new CSP plant.

-

Find environmentally friendly alternatives to non-recyclable things.