The word that pops up in mind when we hear the words fossil fuels is ‘non-renewable’. Coal, crude oil and natural gas are all fossil fuels and are used to produce diesel, gasoline, and kerosene. Fossils fuels formed millions of years ago from the remains of organic matter from dead animals and plants.

As fossil fuel resources are finite and are among the biggest contributors to climate change, it is critical that we meet our energy needs from renewable resources. India’s renewable energy resource potential is significant, with solar, wind, biomass, and small hydropower representing the technologies having the largest potential. Among all, biomass warrants special attention. All the living matter present on earth derived from growing plants including algae, trees, and crops or from animal manure is called biomass.

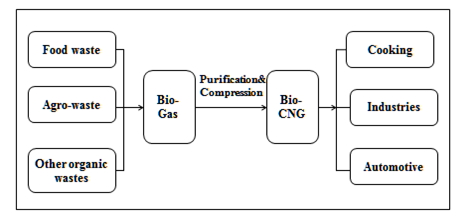

In India traditionally biomass had been utilised either through direct combustion or anaerobic digestion. Anaerobic digestion of biomass is the process in which organic matter, in the absence of oxygen, is mainly transformed into a mixture of methane and carbon dioxide which is usually referred to as biogas. The first experiment on biogas production was done in 1939 by S.V. Desai, the pioneer of anaerobic digestion in India. When this mixture is further processed, purified and compressed it is called Bio Compressed Natural Gas (Bio-CNG). It is similar to natural gas in terms of its composition and properties.

Bio-Gas to Bio-CNG

Biogas consists mainly of methane (CH4, 55-65%) and carbon dioxide (CO2, 35-45%) and the calorific value of biogas is ~19500 KJ/Kg. Methane is a valuable form of gas, as it is an efficient energy carrier with a wide range of uses. The amount of CO2 that is produced corresponds to the amount of CO2 captured when the biomass was created, making biogas carbon neutral.

Aside from methane and CO2, biogas also contains trace components like water vapor, hydrogen sulfide (H2S), siloxanes, hydrocarbons, ammonia, oxygen, carbon monoxide, and nitrogen. The proportion of these trace components depends on the source of the biomass. The presence of water vapor, H2S, and CO2 make biogas very corrosive and unsuitable to be used as fuel. If this biogas is used as fuel in automobiles it can cause erosion of the metal parts, which in turn increases the maintenance cost of the vehicles. In order to tackle this problem the solution that is available is to upgrade biogas.

Biogas upgrading or purification is the process by which contaminants in the raw biogas stream are absorbed or scrubbed, leaving more methane per unit volume of gas. This final product is called biomethane. The most widely used technologies for biogas upgrading are water scrubbing, Pressure Swing Adsorption, membrane, and chemical scrubbing. Of these technologies, water scrubbing and Pressure Swing Adsorption are considered to be most appropriate on a small scale due to low cost and easy maintenance. Biomethane can also be compressed and bottled into cylinders and it is called Bio-Compressed Natural Gas (Bio-CNG) or simply Compressed Bio-Gas (CBG).

(Source: Author)

Why Bio-CNG?

Bio-CNG contains about 92-98 % of methane and only 2-8 % carbon dioxide. The calorific value of Bio-CNG is about 52,000 kilojoules (kJ) per kg, which is 167 % higher than that of biogas.1 The high methane content and calorific value combined with the low quantity of moisture, hydrogen sulphide and impurities makes Bio-CNG an ideal fuel for automobiles and power generation. The low emission levels of Bio-CNG also make it a more environment-friendly fuel than biogas.

Compressed biogas is exactly similar to the commercially available natural gas in its composition and energy potential. Given the abundance of biomass in the country, compressed biogas has the potential to replace CNG in automotive, industrial and commercial uses in the coming years. The potential for compressed biogas production from various sources in India is estimated at about 62 million tonnes per annum and also help bring down dependency on crude oil imports.2 Bio-CNG also holds great promise for efficient municipal solid waste management and in tackling the problem of polluted urban air due to farm stubble-burning and carbon emissions. The Bio-CNG process also produces enriched organic manure which can be used as fertiliser. As Bio-CNG has a high calorific value it also finds its use in blast furnaces.

As production of Bio-CNG from biogas is a new technology there may be some challenges in adopting this technology:

-

The capital cost for installing a Bio-CNG is expensive. E.g. to produce 400 kg/day of Bio-CNG requires a capital investment of Rs. 1.65 crores while 5000 kg/day requires Rs.16 crores.3 4

-

Preliminary processes like collection, transportation, and segregation may also limit the adaptation.

-

It can be installed only where waste generation is abundant. It is challenging to assure waste sources for the production of Bio-CNG and it will not be consistent.

-

The production process requires skilled technicians.

-

There are no specific standards existing in India for installation, operation, and maintenance of these plants.

Status of Bio-CNG in India

In India, Bio-CNG is estimated to replace two-thirds of India’s Natural gas imports, which is currently at 429 billion cubic feet.3 In July 2016, the Waste to Energy Division of MNRE launched a programme on energy from urban, industrial and agricultural wastes/residues which aims to promote setting up of projects for recovery of energy in the form of biogas/Bio-CNG/enriched biogas from urban, industrial, and agricultural wastes. Central Financial Assistance (CFA) of INR 4 crore per 4800 kg of Bio-CNG/day generated from 12,000 cubic metre Biogas /day has been announced, with a limitation of Maximum CFA as INR 10 crore/project).4

Presently, there are seventeen Bio-CNG plants operational in India, with a combined capacity of 46,178 kg per day (Figure 2). These plants are spread over nine states, of which Maharashtra leads in terms of the largest capacity as well as the highest number of plants. In addition, the National Agricultural Cooperative Marketing Federation of India is planning to develop a Bio-CNG facility near Azad Mandi in New Delhi.

Case Studies:

I) Mahindra World City, Chennai

The Bio-CNG plant at the Mahindra World City in the outskirts of Chennai city converts 100 per cent of the eight tons of food and kitchen waste generated daily in the city into 1000 cubic metre of raw biogas. This raw biogas can be enriched to yield 400 kg/day of purified CNG grade fuel which is equivalent to a 200 kW power plant. As a by-product, 4 tons of organic fertiliser is produced every day.6, 7 The Bio-CNG is effectively used to replace CNG as an automotive fuel (for CNG buses and tractors) and LPG for cooking purposes, as well as to power street lights at Mahindra World City.

II) Carbon Masters, Bengaluru

The Bio-CNG plant located in Malur in Kolar District, Karnataka has a production capacity of 1.6 tonnes of Bio-CNG per 40 tonnes of wet waste. Their fertiliser production is still in the emerging stage, producing 1 tonne against the capacity of 8 tonnes. The plant started its operations in the middle of 2017 to recycle 33 tonnes of wet waste from Bengaluru. The gas is stored in cylinders and sold under the brand name of Carbolite, which is the first bottled Bio-CNG supplied to consumers in India. Each unit consists of four cylinders (each 25 kg) and that could save approximately 15 per cent in terms of consumption and cost when compared to existing CNG/LPG.8 They are currently supplied to eight restaurants and commercial establishments in Bengaluru, which uses an average of three units of Bio-CNG in four weekdays.

Given the huge amounts of waste generated in the country, Bio-CNG will certainly emerge as a more feasible option than CNG.

Footnotes:

1. From Biogas to Bio-CNG https://bit.ly/2P4Koc4

2. Compressed biogas as an alternative, green transport fuel https://bit.ly/2ES6CvY

3. Financial Analyses of Biogas to Bio CNG projects in India; Projections based case study analyses https://bit.ly/2J87KzQ

4. India’s first Bio-CNG plant https://bit.ly/2NLtgsO

5. From Biogas to Bio-CNG https://bit.ly/2P4Koc4

6. Bio-CNG at Mahindra World City Chennai. https://bit.ly/2EQusXR

7. Mahindra inaugurates Bio-CNG plant at Mahindra World City https://bit.ly/2G0R1tm

8. How this Bengaluru company is leading the way in turning wet waste into green fuel https://bit.ly/2UsSNOh

Add new comment