Brief overview of the tea industry in India

India is the second largest tea manufacturer in the world after China, with around 1.4 million tons of tea produced in FY 2022-2023, in India. About 80% of tea produced is consumed domestically and the remaining 20% is exported to other countries. The cultivation of tea across India's vast landscapes spans an area of approximately 6.2 lakh hectares. In India tea is auctioned at an average price of ₹ 180 / kg. The Tea Board of India, headquartered at Kolkata, plays a crucial role in promoting and regulating the tea industry in the country. It works towards ensuring the sustainability and growth of the industry while also safeguarding the interests of tea growers, producers, and consumers.The tea industry is an energy-intensive industry, falling under the category of micro, small and medium enterprises ( MSME ) sector. By optimizing energy consumption, tea manufacturers can not only reduce costs but also contribute to environmental sustainability.

CAG’s Energy Audit Initiative in Tripura’s Tea Industries

As a part of Accelerating Clean Energy Transition project, a team from CAG, Chennai conducted detailed energy audits in three tea factories in the state of Tripura in September 2024. The aim was to assess the energy consumption patterns within the tea industry and to identify potential strategies for energy conservation in tea factories. The following three tea factories were selected for our study after discussion with Tea Board officials in Kolkata and Tripura, as these factories are run by a cooperative society formed by the workers of the tea garden.

- Durgabari Tea Estate Workers Co-operative society Ltd, Tebaria, Tripura ( W )

- Ludhua Cha Bagan Sramik Samabaya Samiti Ltd, Sabroom, Tripura ( S )

- Leelagarh Cha Bagan Sramik Samabaya Samiti Ltd, Sabroom, Tripura ( S )

This article serves as a precursor to a comprehensive energy audit report that is currently under development, and will delve into understanding the tea manufacturing process, equipment used in the tea industry, and energy conservation opportunities.

Fig 1.1 : Durgabari Tea factory : Meeting with Factory Incharge

Fig 1.2 : Ludhua tea Factory : CAGs Energy Audit team with factory workers

Fig 1.3 : Leelagarh tea Factory : CAGs Energy Audit team with factory workers

The Tea Production Process

Green tea leaves serve as the primary raw material for various tea types. The tea industry uses three primary methods for tea production : CTC (Cut, Twist, and Curl), Orthodox, and Green Tea.

- CTC Tea : CTC tea, comprising over 85% of the market, undergoes a mechanized process that cuts, tears, and curls leaves into small, uniform pieces. This method yields a strong, bold flavor with a higher caffeine content and a distinctive dark pellet or powder appearance.

- Orthodox Tea : In contrast, orthodox tea involves a more artisanal approach, using traditional machinery or even manual techniques. This process results in a delicate, nuanced flavor with lower caffeine levels. Orthodox teas are typically sold in loose-leaf or whole-leaf form, often used for premium black teas.

- Green Tea : Green tea is produced by steaming or pan-frying leaves immediately after plucking, to prevent oxidation. This method preserves the leaves' natural color and flavor, resulting in a fresh, vegetal taste with a higher antioxidant content. Green tea is often characterized by its slightly curled leaf appearance.

In the three tea factories we visited, almost all of them manufactured only CTC tea. (Ludhua tea factory produces orthodox tea and green tea along with CTC tea. However, the production of these varieties is significantly smaller compared to the factory’s CTC output).

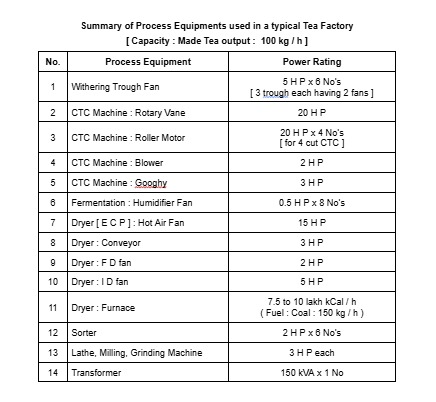

The final product of tea coming out from the tea factory is known as “Made tea”. For producing one kg of Made tea around 5 kg of green leaves is required.The tea industry uses both thermal and electrical energy for tea production. There are around 8 major operations involved in CTC tea production and these are briefly described below with relevant photographs.

- Collection of green leaves

- Withering ( partial removal of moisture by atmospheric air drying )

- Shredding

- Cutting, Tearing and Curling ( CTC ) ( Size reduction )

- Oxidation / Fermentation ( Bio-chemical reactions in the presence of oxygen )

- Drying ( moisture removal and stoppage of fermentation )

- Sorting ( fibre removal; grading based on size )

- Packing & Transportation

Tea Production Process : Flow Chart

Of these 8 processes involved, chemical changes occur primarily in withering, fermentation & drying operations and these in turn influence the quality of tea produced.

1. Collection of Green Leaves

The tea industry in India features two primary models: large tea estates with their own factories and bought leaf factories that purchase leaves from smaller growers. All three tea factories included in our study are owned by tea estates that cultivate their own tea leaves. While they may also process leaves from external sources when their own gardens cannot meet demand, their primary focus remains on processing their homegrown leaves. Collection of green leaves is primarily done by hand.

Fig 2 : Durgabari Tea Garden, Tripura

2. Withering

Withering is a crucial step in tea processing that prepares the freshly harvested green leaves for subsequent stages like rolling and fermentation. By carefully removing surface moisture while retaining some internal moisture, withering creates the ideal physical conditions for these processes. The withering process involves both biochemical and physical reactions. These reactions help to soften the leaves and prepare them for the enzymatic changes that occur during fermentation. Green leaves are typically placed in withering troughs for a period of 8 to 12 hours. These troughs, often measuring 100 feet by 12 feet, can hold approximately 2,000 kilograms of leaves per batch. Air is circulated through the leaves spreaded in the troughs over a wire mesh, removing excess moisture. This physical withering process is aided by blowers that pass the air through the leaves from the bottom. In addition to physical changes, chemical withering also occurs during this stage. This process is influenced by factors like time and temperature and plays a vital role in determining the quality of the final tea product. The goal of withering is to reduce the moisture content of the green leaves to around 70%. Proper withering enhances the flavor index and aroma of the tea. Blowers used in withering troughs typically have a power rating of around 5 horsepower and a CFM (cubic feet per minute) rating of 50,000 to 75,000. These blowers ensure efficient air circulation and moisture removal.

Fig 3 : Withering Trough : Layout | CAG

Fig 4 : Withering Trough Fans in Ludhua Tea Factory, Tripura

Fig 5 : Withering Trough in Leela Garh Tea Factory, Tripura

3 . Shredding and Rolling ( CTC )

Upon withering, the leaves become flaccid. These flaccid leaves are crushed by means of rotor vane shredder. A reconditioned powder ( made of pulverized fly-off from dryer or fibre removed during grading ) is added to compensate for any loss of juice from tea leaves during shredding. Rolling is carried out to crush the leaves into small bits and to press out the juice for coating it over the leaf particles. Good quality crushing is achieved when the speed of rotation of the two rollers is maintained in the ratio 1 : 10. During rolling, the heat generated through friction reduces moisture of the leaves to 55 %. Depending on the grade of tea, 3 to 4 CTC machines are used. Apart from twist and curl, the enzymes released during rolling help in fermentation. Through this process of crushing and rolling, the polyphenols and enzymes get mixed and coated over the leaves in the presence of oxygen. When these 3 elements ( Polyphenol, Enzymes & Oxygen ) are mixed in proper proportion, fermentation gets activated. The quality of fermentation determines the quality of the final product. A four - cut CTC machine typically consists of seven motors : Shredder ( 20 HP ), Blower ( 2 HP ), CTC Roller ( 4 x 20 HP ), Rotary shifter or Rotating drum ( ‘Ghooghy’ ) ( 3 HP ). All the three factories we visited had only 4 Cut CTC machines.

Fig 6 : CTC machine : 4 Cut : Layout | CAG

Fig 7 : CTC Machine : Durgabari Tea Factory, Tripura

4) Fermentation

Fermentation is an oxidation process through which the polyphenols in the leaf get oxidized with the help of endogenous enzymes. The fermentation process is done naturally or in a rotating drum. Fermentation of rolled tea leaves turns them to a brown colour. Short or light fermentation gives more flavoured and aroma rich tea, whereas long or deep fermentation forms rich colour in tea brewing. The factors that influence good quality fermentation are time, temperature, humidity, aeration, spreading thickness, and cleanliness. In the tea factories we visited they mainly perform natural fermentation, in which the rolled leaves are spread over the floor and humidifier fans ( 5 to 10 numbers ) each rating 0.5 HP is used to maintain the humidity of the rolled leaves ( wet dhool ).

Fig 8 : Fermentation : Durgabari Tea Factory, Tripura

5) Drying

The product obtained on completion of fermentation is called wet dhool. This dhool is subjected to drying for eliminating the surface and core moisture thereby arresting the fermentation activity. Most of the dryers used in the tea factories are continuous flow type dryers known as Endless Chain Pressure [ E C P ] dryers. The conveyors / tray containing the wet dhool moves inside the drying chamber. Hot air at 90°C to 110°C is blown over the wet dhool. The hot air is produced by indirect heating of fresh air sucked from the atmosphere passing over heater coils heated by flue gas from a coal / biomass furnace or directly heating of atmospheric air using natural gas burners. In some places Fluidized Bed Drying ( F B D ) is practiced for drying due to its versatility, flexibility and effectiveness and in the FBD dryer, temperatures of 140°C to 160°C is maintained. The quality of tea produced strongly depends on the drying technique practiced and the final moisture content of the product. In drying operation, moisture is removed from the fermented wet dhool indicated by the change of colour of dhool from coppery red to black. This color change indicates the stoppage of the fermentation process in drying. Normally, the fermented dhool entering the drier has a moisture content of 50 % to 55 % and the final product coming out of driers i.e., dryer mouth tea ( dry dhool ) contains 3 % to 4 % moisture. A typical dryer used in the tea factory has a production rate capacity of around 100 kg / h ( dryer mouth tea ). It uses both thermal and electrical energy for its operation. The main equipment consuming electrical energy is Hot Air Fan ( which sucks the atmospheric air inside the dryer ) whose rating is around 15 H P. Also for heating of air, a typical 100 kg / h output dryer consumes 150 kg / h of coal or 250 kg / h of biomass.

The three tea factories studied employed different dryer fuel sources: Durgabari Tea Estate utilized a natural gas-powered ECP dryer, while Ludhua and Leelagarh Tea Factories used coal-fired ECP dryers. The choice of fuel was influenced by the availability of natural gas connections in Durgabari, which is located near Agartala, and the lack of such connections in Ludhua and Leelagarh, located near Sabroom, a town down south in Tripura.

Due to the environmental concerns associated with coal handling, there is a promising opportunity to replace coal with biomass-based fuels in the dryer furnaces of Ludhua and Leelagarh. With minor modifications, these factories could transition to using biomass, thereby reducing pollution and promoting a more sustainable approach to tea production.

Fig 9 : ECP Dryer : Layout | CAG

Fig 10.1 : Dryer : Ludhua Tea Factory

Fig 10.2 : CNG based ECP dryer : Durgabari Tea Factory

Fig 10.3 :Coal Based ECP dryer : Leelagarh Tea Factory

Fig 10.4 :Smoke from Chimney : Coal based Dryer : Leelagarh Tea Factory

Fig 10.5 : Coal storage : Ludhua Tea Factory, Tripura

Fig 10.6 :Coal feeding to the Furnace of the dryer : Ludhua Tea Factory

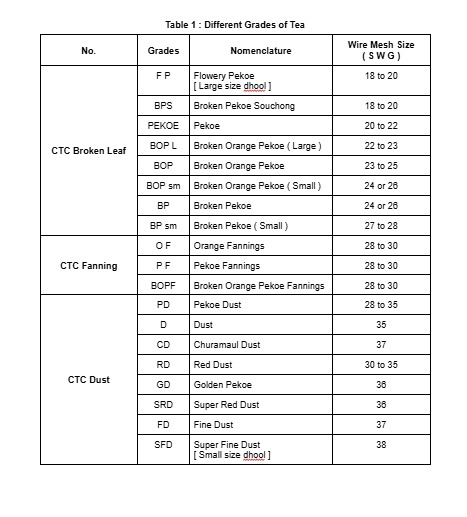

6) Sorting / Grading

- Sorting is a crucial step in tea processing that separates bulk tea ( dryer mouth tea) into different grades based on size. This process is achieved using a machine equipped with various sized meshes.

- Different grades of tea are obtained by passing the tea through these meshes. For example, BOP sm (Broken Orange Pekoe Small) is typically sold at a higher price due to its superior taste and aroma, while fine dust is often the least expensive grade.

- Sorting machines require several small motors to power the vibration of the meshes and the movement of conveyors. A typical sorting section in a tea factory may use between 10 and 15 motors, each with a power rating ranging from 1 to 3 horsepower.

Fig 11 : Different grades of tea : BOP ( L ), BOP (sm), Dust

Fig 12 : Sorting Machine : Ludhua Tea Factory, Tripura | CAG

Fig 13 : Different stages of tea processing

7) Packing & Transportation

- The tea produced is packed ( based on their grades ) in food grade quality bags and transported for auction / sale.

Fig 13 : Packing Section : Durgabari Tea Factory, Tripura

Energy Consumption

A typical tea factory in Tripura ( Ludhua Tea factory ) processes 5,00,000 kg of green leaf annually, producing 1,00,000 kg of made tea. For the tea production process, the factory consumes 50,000 kWh of electricity and 1,40,000 kg of coal per year. ( Megalayan coal GCV : 5500 kCal )

Fig 14: Energy consumption in tea production

Specific Energy consumption

- Specific energy consumption [ S E C ] is a key performance indicator that measures the amount of energy required to produce a unit of output. In the tea industry the S E C refers to the energy consumed (including both electrical and thermal) per kg of made tea production.

- Determination of the S E C helps to compare the energy efficiency of different tea factories. Low specific energy consumption can lead to significant cost savings and increase the competitiveness in the market.

- Specific Energy Consumption of Ludhua Tea Factory is computed and presented below:

- Electrical Energy : 0.5 kWh / kg made tea ( 5 % of total energy )

- Thermal Energy : 1.4 kg of coal / kg made tea ( 95 % of total energy ), equivalent to 9 kWh / kg made tea

- Total Specific Energy Consumption : 9.5 kWh to 10 kWh / kg made tea

Cost Share for energy consumption

- Electrical Energy : ₹ 5 / kg made tea ( 20 % of cost for energy per kg of tea)

- Thermal Energy : ₹ 20 / kg made tea ( 80 % of cost for energy per kg of tea )

Total Energy Cost : ₹ 25 / kg made tea

Fig 14 : Tea Production : Energy Share and Energy cost

Energy Conservation strategies and opportunities in a Tea Factory

Withering

- Maintain a difference of 4°C between dry bulb temperature and wet bulb temperature in the withering trough inlet air for better withering conditions.

- Use either Programmable Logical Controller ( PLC ) or Variable Frequency Drive ( VFD ) to control withering fans instead of damper control.

- Reduce air flow in artificial withering process to about 2/3rd of the volume after completion of withering process to avoid spoiling of withered leaves.

- Use of Fibre Reinforced Plastic ( F R P ) material for withering Fan Blades. ( Energy Saving 10 % compared to metal based fans )

CTC

- Use low pressure roller for under withered leaves and high pressure roller for over withered leaves.

- Use optimum loading during rolling process

- Limit motor rewinding up to two times.

Fermentation

- Regulate and control the use of humidifiers used for floor fermentation

- Use ball breaker after fermentation to avoid ball formation.

Dryer

- Use suitable measures to control air flow and temperature in dryer : Blower speed control usingVariable Frequency Drive ( VFD ) or automatic temperature controller.

- Maintain correct combustion air ratio in the dryer furnace using oxygen analyser

- Use better insulation material to avoid heat loss

- Minimize heat loss through air ingression by adopting proper sealing and minimal opening.

- Install blower having suitable capacity and correct pressure. Avoid using oversized or undersized blowers for dryers.

- Install blower close to the combustion equipment to avoid transmission loss.

- Use of FBD dryer instead of ECP dryer ( Energy saving 10 to 15 % )

- Use of Energy Efficient Modulating Burners which are provided with variable air / fuel ratio leading to better heat generation and drying of leaves, thereby producing good quality tea

- Use of biomass or gaseous fuel instead of coal for hot air generation in the dryer.

General

- Install automatic voltage regulator ( A V R ) for controlling variations in voltage from grid power.

- Ensure unity power factor using automatic power factor controller ( A P F C )

- Replace standard motors with energy efficient IE3 or higher motors

The Indian tea industry has a significant opportunity to embrace sustainable practices like use of energy efficient equipment, renewable energy utilization. By optimizing energy consumption throughout the production process, tea manufacturers can reduce costs, minimize their environmental footprint and also enhance its global competitiveness. Collaboration between industry stakeholders, government agencies and research institutions can drive innovation and promote sustainable practices in the tea industry.

Add new comment